The stress vortex flowmeter

Products overview:

ZW - LUGB seriesStress typeVortex street flowmeterMainly used in industrial pipeline medium fluid flow measurement, such as gas, liquid and vapor, and other media.Is characterized by small pressure loss, wide range, high precision, working condition of the measurement volume flow is almost not affected by the fluid density, the influence of the parameters such as pressure, temperature, viscosity.No moving mechanical parts, so high reliability, small amount of maintenance.Instrument parameters can be long-term stability.Using piezoelectric stress sensor, high reliability, can be in - 20 ℃ ~ + 250 ℃ temperature range.There are standard signal simulation and digital pulse signal output, easy with the computer and digital systems, is a more advanced, the ideal flow meter.

Second, the working principle:

ZW - LUGB seriesStress typeVortex street flowmeterVertical in the measurement of tube inserted a pillars, on both sides of the fluid through the pillars is alternately with the rules of the vortex, the spiral column is called the karman vortex street.The release of the karman vortex street frequency is related to the width of the fluid velocity and pillars, expressed by the type:

F = St · v/d type: - the release of the karman vortex street frequency f

St - coefficient (called, ha)

V - velocity

D - the width of the pillars

Karman vortex street release frequency f and is directly proportional to the velocity v, so by measuring the karman vortex street release frequency to calculate the instantaneous flow rate.

Stern lo ha is one of the important coefficient of vortex flowmeter.In its number of St 0.17 straight part of the material, the release of the vortex frequency is proportional to the velocity of flow, so check out the velocity v, frequency f can be obtained to calculate volume flow by v.

Vortex flow sensor be vortex frequency is applied to detect sensor by vortex alternately (probe) on in-situ stress in its internal piezoelectric element to check out.

Applications:

ZW - LUGB seriesStress typeVortex street flowmeterWith wide range than, high precision, easy installation and maintenance and a series of advantages such as wide adaptability of medium.Can be widely used in petroleum, chemical industry, metallurgy, machinery, food, papermaking, and urban pipeline heating, water supply, gas and other industries of all kinds of low viscosity liquid, gas, steam, etc of single-phase fluid process measurement and energy saving management.

Four, the main features:

1, with low power consumption CPU processor, and liquid crystal display (LCD), low power consumption.

2, installation is simple, maintenance is very convenient, the verification cycle is long, generally for two years.

3, simple structure, no moving parts, long running is very reliable.

4, span a wide range: 1:10 normal range, the range can be up to 1:15.

5, small pressure loss, low operating cost, more energy saving.

6, within a certain Reynolds number, the output signal from the measured media and changes in the composition, physical properties of instrument coefficient only involved in the body shape and size of the vortex, generally do not need to calibrate the instrument coefficient after changing accessories.

7, scene shows, but also long distance transmission, also can connect with the computer control system.

8, detecting probe measured medium, not direct contact with more stable performance.

9, temperature, pressure compensation integration design, the output current are photoelectric isolation, has the good ability to resist common mode interference suppression.

Five, the technical parameters:

Piezoelectric type, temperature range: 1: - 25 ℃ ~ + 350 ℃ capacitive: - 40 ℃ ~ + 450 ℃

2, the connection way: DN15 ~ 12 for flange mounted flange connection type, from 12 to DN1000 plug-in, DN1000 above are special orders

And velocity range: 3:7 m/s ~ 70 m/s liquid: 0.7 m/s ~ 7 m/s gas: 5 m/s ~ 35 m/s

4, pressure specifications: PN1.6 MPa;PN2.5 MPa;Specifications can be customized special PN4.0 MPa, higher pressure

5, the pressure loss coefficient: Cd 2.6 or less

6, accuracy: flange mounted, connection type: 0.5, 1.0, 1.5 plug-in: 1.5, 2.5

7, the power supply voltage: sensors: DC12V or DC24V transmission: DC24V

The display type: DC24V, DC12V or 3.6 V lithium battery

8, output signal, sensor, pulse frequency signal 2 ~ 3000 hz low level 1 v high level 6 v or more or less

Transmitter: two wire system 4 ~ 20 mA DC current signal

9, ant-vibration performance: piezoelectric capacitive acuities were 2.0 g 0.2 g or less

: 10, environment temperature sensors: - 30 ℃ ~ + 65 ℃ transmitter: live show - 10 ℃ to + 50 ℃

11, environment humidity: 5 ~ 8% relative humidity

12, signal remote transmission distance: 500 m or less

13, straight pipe length: 10 d or higher downstream p 5 d

14, explosion-proof grade: Exia Ⅱ CT2 - T5 safety explosion-proof

15, protection grade: regular IP65 diving IP68

16, instrument material: instrument shell adopts aluminium alloy, the table body part adopts 304 stainless steel material, also can according to user requirements the use of special materials.

Six, selection of key points:

Correct selection to ensure that the use of vortex flowmeter is better.Should choose what kind of vortex street flowmeter is based on the current body to determine the physical properties and chemical properties of the medium?Make the size of vortex flowmeter, flow range, lining materials, electrode materials and output current, etc?To be the nature of the flow volume and flow measurement requirements.

1, precision function

Precision grade and function in accordance with the requirements of measurement and choose the instrument using fine grade, cost-effective.Such as for trade settlement, product transfer and energy measurement occasions, should choose high precision grade, such as 1.0, 0.5, or higher level;Used in process control, according to the requirements of control choose not with precision grade;Some just check process flow, without having to do precise control and measurement, can choose lower precision grade, such as 1.5, 2.5, 4.0, and even then you can choose cheap plug-in vortex flowmeter.

2, medium can be measured

Medium velocity and diameter, full scale measurement generally medium, the full flow of vortex flowmeter can measure medium velocity in 0.5-12 m/s within the scope of selection, range is wide.Choose different instrument specifications (diameter) and process piping, the same shall consider whether measuring flow range within the scope of the flow velocity, namely when the pipeline flow rate is low, can not meet the requirement of the flow meter, or under the velocity measurement accuracy of the quasi cannot guarantee, the need to reduce the size instrument, which carry high tube flow velocity, measurement results are satisfied.

3, the selection of vortex flow transmitter

In saturated vapor measurement using VA type piezoelectric vortex flow transmitter, due to the vortex flow meter range wide, therefore, in practice, the measurement of saturated steam flow main consideration shall not be less than the lower limit of vortex flowmeters, that is to say, must satisfy the fluid flow rate shall be not less than 5 m/s.According to the size of the YongQiLiang chooses different caliber of vortex flow transmitter, rather than with the existing technology to choose transmitter diameter pipe size.

The choice of 4 pressure transmitter, pressure compensation

Because of the saturated steam pipe length, pressure fluctuation is bigger, pressure compensation must be used, considering the pressure, temperature and density, the relation between measurement using pressure compensation, because the pipeline saturated steam pressure in the range 0.3 0.7 MPa, pressure transmitter ranges 1 MPa.

5, display instrument selection

Display instrument intelligent flow display, a voltage compensation, the instantaneous flow and cumulative flow integrating function.

Seven, requirement for straight pipe:

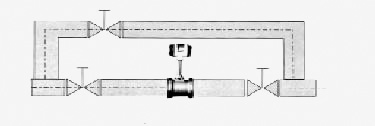

In order to ensure that the instrument, accurate to run normally, sensor must have a certain straight pipe upstream and downstream of the installation points, to adjust the flow field, as shown.

Figure 1: concentric contraction tube;

Figure 2: the concentric expansion tube;

Figure 3: a 90 - degree Angle;

Figure 4: the same plane of two 90 - degree Angle;

Figure 5: different plane of two 90 - degree Angle;

Figure 6: regulating valve should be installed downstream of the sensor in 5 d to the distance, if the sensor must be installed in the upstream, the sensors should be not less than 50 d upstream, straight pipe section downstream straight pipe section should be not less than 5 d.

Eight, the requirement of pipe:

1, upstream and downstream piping diameter D, and the same as the sensor inner diameter DN, its difference satisfy the following conditions: 0.95 DN D 1.1 or less or less DN.

In 2, piping should be one of the sensor, the coaxial degree should be less than 0.05 DN.

3, gasket not protruding into the pipe, the inner diameter slightly larger than sensors.

4, if you want to stop inspection and cleaning the sensor, the by-pass pipe should be set up, as shown in the figure below.

Nine, the requirement of pipe vibration:

Sensors to avoid installed on the strong pipeline vibration, if necessary to install, shock absorption measures must be taken, respectively at the upstream and downstream of sensor 2 d piping fastening device, and vibration-proof pad.

Special note: in the air compressor exit strong vibration, cannot install the sensors, shall be installed after the gas storage.

Ten, field requirements:

1, low maintenance - most of the vortex flowmeter are on the market with induction swirl hole or plug-in measurement, once the impurities embedded in the medium pressure hole or sensing element and the table body, the gap between the signal is weak or unstable.A good design should be not easy to plug part, thereby reducing amount of maintenance.

2, inductive components online replacement - some manufacturer of inductive components and vortex street close 2 for one, seemingly simple design to the actual use of inconvenience.Because once induction part failure, you need to medium to the pipe emptying replacement parts, after pressure relief effect production.Perfect design should be separated the two, so can replace the induction part alone, without emptying the media.

3, vortex flowmeter is vulnerable to vibration interference, well-designed vortex flowmeter can through hardware and digital signal processing to exclude interference, and the stability of the signal is obtained.

4, vortex flow meter before and after the installation of a hassle to very long straight section, some manufacturers can offer within the flowmeter reducing design, greatly reduces the user specifically MenWei vortex flowmeter with the demand of the straight pipe.

During 11, debugging use need to be aware of problems:

1, flowmeter, on-site installation, maintenance, must abide by the "explosion-proof gas do not open" warnings, and in the open before turn off the power supply.

2, vortex flow meter used in outdoor, suggestion and side shields.

3, shall not be arbitrarily fixed part loosen the flowmeter.The protection of the pressure sensor.Users in the use of traffic time, should pay attention to the flow pressure overload value of pressure sensor is rated working pressure of 1.5 times (that is, the media zui high pressure of 1.5 times).Selection should be within the prescribed flow range, prevent overspeed operation, in order to obtain the ideal accuracy and ensure the normal service life.(due to pressure test, purging pipes or exhaust overdrive, and turbine operation in the reverse flow meter can cause damage)

4 when put into operation, the vortex street flowmeter, should slowly open valve, prevent damage of instantaneous flow and the turbine.Add lubricant should be according to the sign, the number of refueling depends on temperament clean degree, usually 2 ~ 3 times a year.

5, vortex street flowmeter runtime or alternate internal related parameters are not allowed to open the rear cover, otherwise will affect the normal operation of the meter.

Twelve, appearance size:

DN | A | B | C | D |

15 | 90 | Φ 57 | 383 | 45 |

20 | 100 | Φ 57 | 388 | 50 |

25 | 100 | Φ 57 | 394 | 50 |

32 | 100 | Φ 65 | 396 | 50 |

40 | 100 | Φ 75 | 401 | 50 |

50 | 110 | Φ 87 | 407 | 55 |

65 | 110 | Φ 109 | 418 | 55 |

80 | 110 | Φ 120 | 423 | 55 |

100 | 120 | Φ 149 | 447 | 60 |

125 | 125 | Φ 175 | 474 | 65 |

150 | 145 | Φ 203 | 501 | 75 |

200 | 170 | Φ 259 | 556 | 100 |

250 | 190 | Φ 312 | 608 | 120 |

300 | 210 | Φ 363 | 660 | 140 |

350 | 230 | Φ 409 | 709 | 160 |

400 | 250 | Φ 460 | 756 | 180 |

450 | 275 | Φ 520 | 814 | 205 |

500 | 290 | Φ 575 | 869 | 225 |

Thirteen, standard of flow range profile: unit (m3 / h)

traffic | The liquid flow range | Gas flow range | Saturated steam flow range | |||

CAL | Small flow | Heavy traffic | Small flow | Heavy traffic | Small flow | Heavy traffic |

DN25 | 0.9 | 14 | 8.3 | 110 | 13 | 1500 |

DN40 | 2.5 | 35 | 26 | 300 | 25 | 4400 |

DN50 | 3.3 | 55 | 36 | 480 | 40 | 6800 |

DN80 | 8 | 150 | 90 | 1300 | 100 | 19000 |

DN100 | 14 | 240 | 140 | 2000 | 160 | 29000 |

DN150 | 38 | 450 | 290 | 4100 | 350 | 66000 |

DN200 | 70 | 850 | 620 | 7500 | 620 | 118000 |

DN250 | 130 | 1300 | 700 | 12500 | 970 | 185000 |

DN300 | 180 | 2000 | 920 | 16500 | 1400 | 267000 |

14, selection of coding:

Code name | size | Flow range ㎡/h(In the wei and control) | ||||

ZW-LUGB-25 | DN25 | 1 ~ 10(liquid) | 25 ~ 60(gas) | Steam flow check specifications,DN300The above recommended plug-in vortex flowmeter | ||

ZW-LUGB-32 | DN32 | 1.5 ~ 18(liquid) | 15-150(gas) | |||

ZW-LUGB-40 | DN40 | 2.2 ~ 27(liquid) | 22.6 ~ 150(gas) | |||

ZW-LUGB-50 | DN50 | 4 ~ 55(liquid) | 35 ~ 350(gas) | |||

ZW-LUGB-80 | DN80 | 9 ~ 135(liquid) | 90 ~ 900(gas) | |||

ZW-LUGB-100 | DN100 | 14 ~ 200(liquid) | 140 ~ 1400(gas) | |||

ZW-LUGB-150 | DN150 | 32 ~ 480(liquid) | 300 ~ 3000(gas) | |||

ZW-LUGB-200 | DN200 | 56-800(liquid) | 550 ~ 5500(gas) | |||

Code name | function1 | |||||

N | No temperature pressure compensation | |||||

Y | With temperature compensation | |||||

Code name | Output type | |||||

F1 | 4-20mAOutput (two-wire system) | |||||

F2 | 4-20mAOutput (three-wire system) | |||||

F3 | RS485Communication interface | |||||

Code name | Measured medium | |||||

J1 | liquid | |||||

J2 | gas | |||||

J3 | steam | |||||

Code name | The connection method | |||||

L1 | Flange mounted | |||||

L2 | Flange connection type | |||||

Code name | function2 | |||||

E1 | 1.0level | |||||

E2 | 1.5level | |||||

T1 | The normal temperature | |||||

T2 | The high temperature | |||||

T3 | steam | |||||

P1 | 1.6MPa | |||||

P2 | 2.5MPa | |||||

P3 | 4.0MPa | |||||

W1 | internal3.6VThe power supply | |||||

W2 | DC24VThe power supply | |||||

N1 | Stainless steel | |||||

N2 | Carbon steel | |||||

N3 | Anti-corrosion type | |||||

15,Order to choose selection guidelines:

Name and model number of 1, 1), (2) the diameter, flow range, (3) whether or not to bring the attached so that we can correct selection for you, (4) using pressure, (5) the use of medium temperature.

2, if has been selected by design units in the way of vortex street flowmeter types, please press type vortex flowmeter directly order from our sales department.

3, when using occasions is very important, or the environment is complex, please try to provide the design drawings and detailed parameters, by wei experts in our audit checks for you.

After-sales service commitment:

1, from the date of signing of the contract, I in the way provided for products of the company offers free maintenance and maintenance service, commitment to lifelong maintenance service;

2, jiangsu wei measurement and control instrument co., LTD. Sales manager will be in regular contact with customers, understand the usage of products, and solve the problems of the customers to use in the process of produce, free of charge to provide technical support;

3 the man-made damage is found, the warranty period, our company is responsible for the maintenance, and the resulting maintenance fee;

4, product quality problems or are not satisfied with product, the user can choose unconditional return, wei tt&c don't charge any fees, appear quality problem, bear the freight back and forth.